Calibration Guide for NATA Facilities Using the Telemetry2U Platform

This guide is primarily intended for NATA-accredited calibration facilities, outlining the process for verifying and calibrating sensors directly on the Telemetry2U platform. However, the same approach can be followed by any organisation or individual with access to reliable calibration equipment and appropriate procedures, ensuring accurate, traceable results.

Preparing Sensors for Calibration on Telemetry2U

If you already have a username and password, please log in to Telemetry2U here. If not, please register an account here and notify us via email at support@telemetry2u.com.

Ensure the Telemetry2U-supplied LoRaWAN gateway is powered, connected to the internet, and within 100 metres of the sensors. It serves as the communication link to the IoT platform. Internet access may be via Ethernet or Telstra 4G (SIM usually pre-installed). You will receive a confirmation email once connected.

Nodes should already be linked to the calibrator’s account and visible on the Reports page. Each node has a structured “node description” containing the DevEUI, sensor types, calibration points, and tolerance:

A8 40 41 40 23 45 64 68 | EXT+INT | -30,0,30 | 0.3

This indicates that node A8 40 41 40 23 45 64 68 must be calibrated at -30°C, 0°C, and 30°C on both internal and external sensors, with a ±0.3°C tolerance. A calibration list should be provided by Telemetry2U for verification.

Getting Started: Powering Up Nodes and Preparing Sensors

Nodes ship powered off. Two common node types are used, each with specific startup and calibration procedures:

Dragino LHT65 with Internal and External Temperature Sensors

- Power-up procedure: Hold “ACT” button for 5 seconds

- Power-down procedure: Press “ACT” button 5 times quickly

- Internal Sensor Resolution: 0.1°C

- External Sensor Resolution: 0.1°C

- Stabilisation Time: 1 hour

- Temperature Limits: -40°C to 85°C

- Expected Accuracy: ±0.5°C

Once powered, the LED flashes green upon connection. On data send, red indicates no external sensor; blue indicates one is installed. Ensure the external sensor is firmly connected before calibration.

Note:

The external temperature sensor is waterproof and should be calibrated in a water bath for best results. However, the node itself is not waterproof and must be calibrated in an environmental chamber.

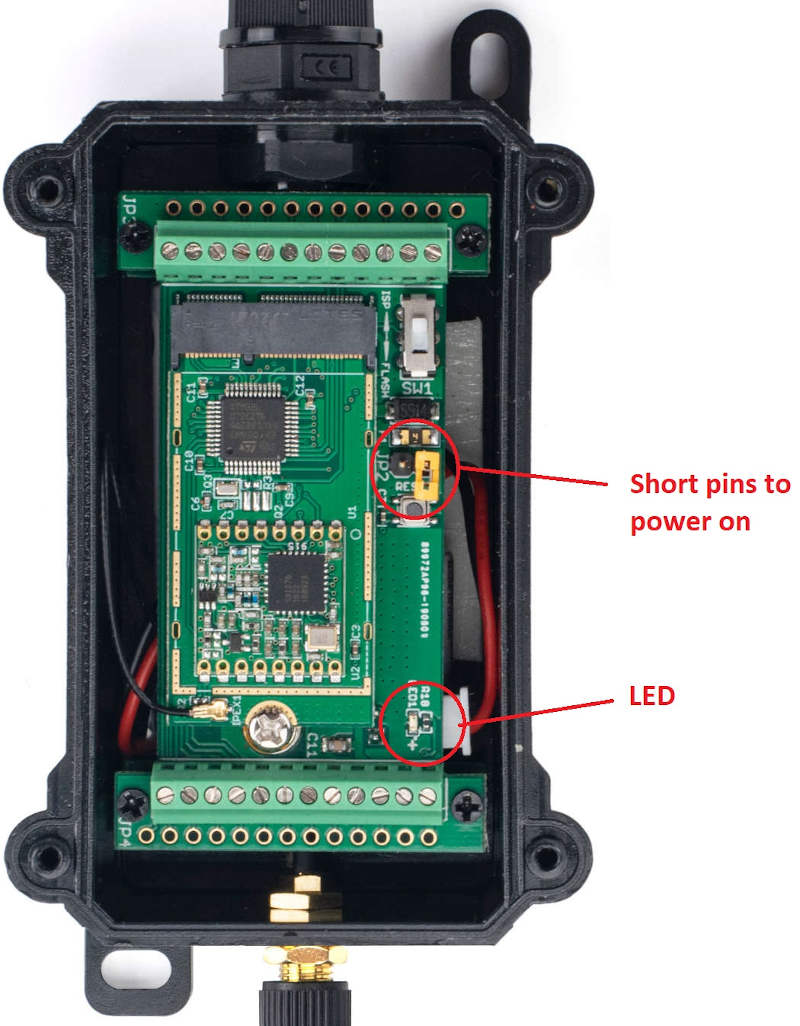

Dragino LTC2-XX with External RTD Temperature Sensor

- Power-up procedure: Rotate jumper to short both pins

- Power-down procedure: Place jumper over one pin only

- External Sensor Resolution: 0.01°C

- Stabilisation Time: 1 hour

- Temperature Limits: -200°C to +200°C

- Expected Accuracy: ±0.2°C

Attach the antenna to the external SMA connector. After power-up, a brief green LED flash followed by a 2-second blink confirms successful network connection.

The RTD sensor is waterproof and should be calibrated in a water bath for best results.

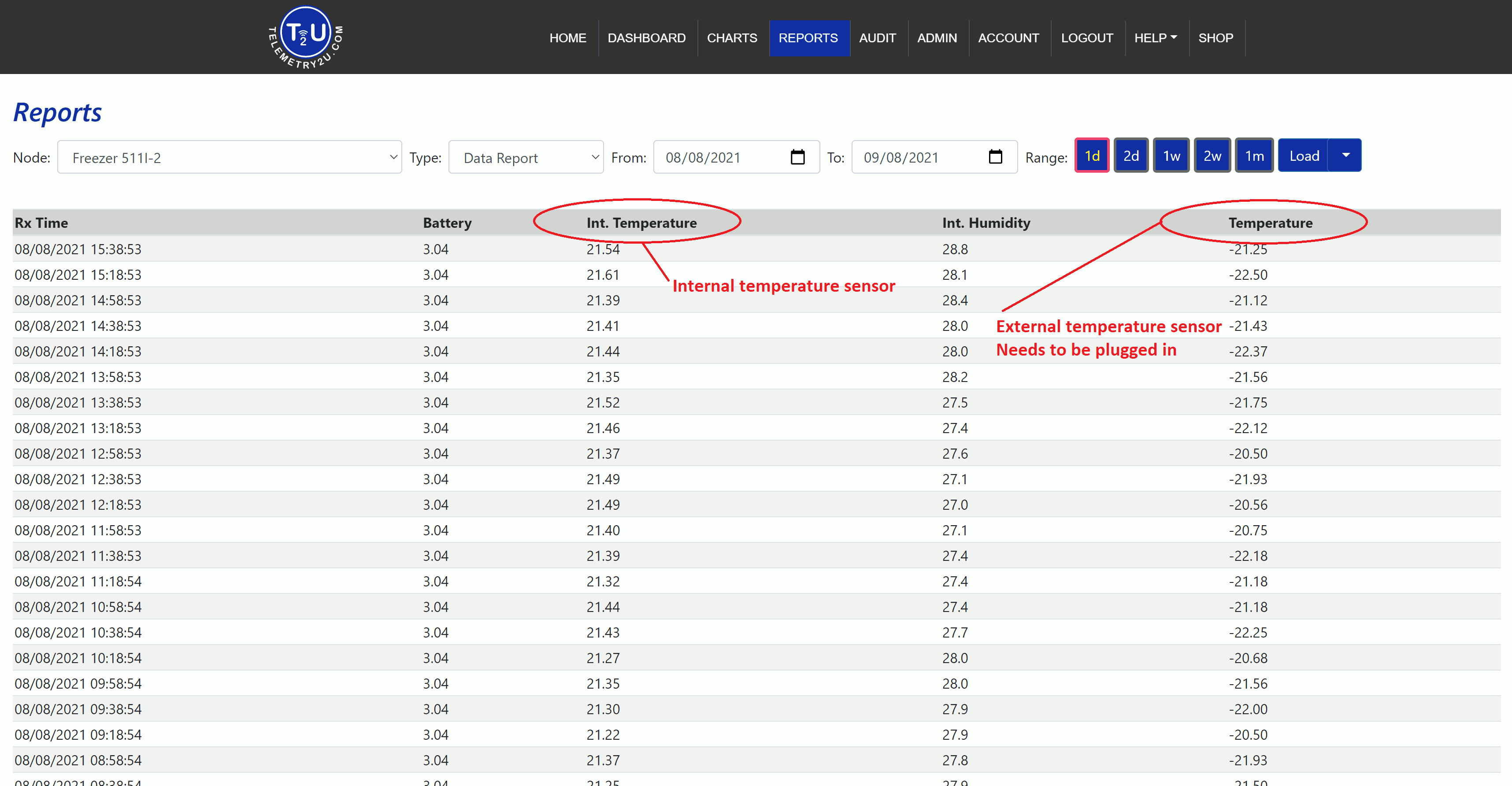

Verify that Data is being received by Telemetry2U

Within 10 seconds of powering up, the sensor node should transmit a record to the Telemetry2U platform and continue sending updates every 2–5 minutes until powered down. The timestamp on the Reports page will update to the current time.

Note: You will need to refresh the page manually to view the most recent data.

For LHT65 nodes, three values are recorded:

- Int. Temperature

- Int. Humidity

- Temperature (external sensor)

For LTC2-xx nodes, only one sensor is recorded:

- Temperature (external RTD)

Calibrating Sensor Inputs on the Telemetry2U Platform

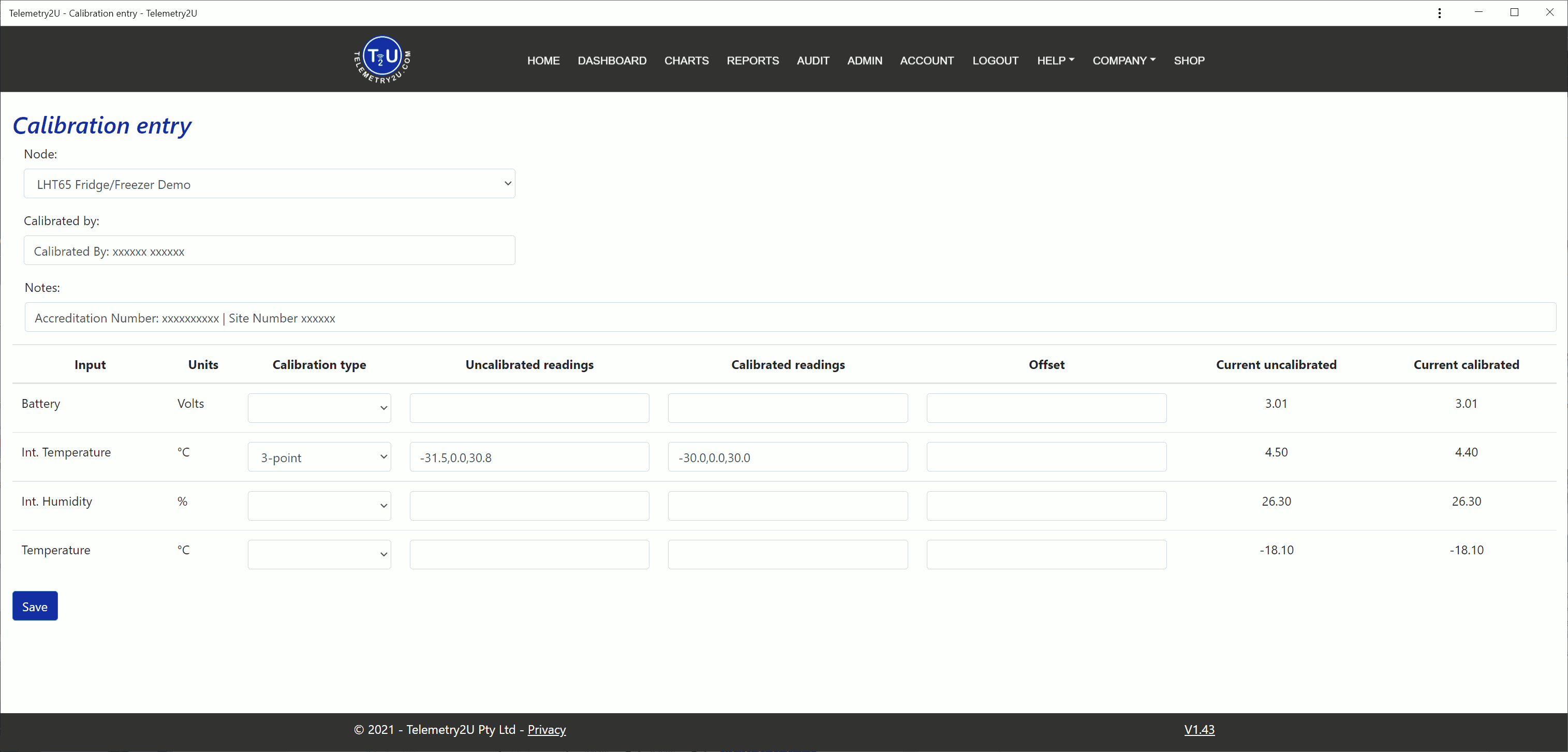

Once your calibration results are verified, you can apply them directly on the Telemetry2U platform via the Calibration page, found under Admin >> Calibrations. The platform supports both 2-point and 3-point calibration methods.

Enter the Calibration Coefficents into the Telemetry2U Platform

To enter calibration data:

- Select the device from the Node dropdown list. This will match the DevEUI sticker on the sensor.

- Enter your company name, accreditation number, and site number in the Calibrated By field.

- If available, enter the calibration certificate number in the Notes field.

For the sensor being calibrated:

- Select 3-point as the Calibration Type.

- “Int Temperature” refers to the internal sensor.

- “Temperature” refers to the external sensor.

Enter the three raw readings from the Reports page (lowest to highest) in the Uncalibrated Readings field, separated by commas (e.g., 1.00,2.00,3.00).

Then enter the corresponding reference thermometer values in the Calibrated Readings field, also in ascending order and separated by commas (e.g., 2.00,4.00,6.00).

All readings must include two decimal places (e.g., 0.00).

Click Save to apply the calibration. The calibration will take effect from 00:00 (midnight) of the current day, and the updated value will appear in the Current Calibrated field.

Note: Power down the devices after calibration is complete to avoid unnecessary battery drain. Instructions for powering down are included in the earlier section.

Record the calibration data on the calibration certificate, and affix a calibration sticker to both the node and the external sensor (if applicable). This completes the calibration process.