Aluminium Temperature Sensor Buffers: Precision in Sample Representation

Telemetry2U's aluminium temperature sensor buffers are engineered to closely replicate the thermal properties of stored samples. By minimising the impact of rapid air temperature fluctuations, these buffers ensure more accurate readings and significantly reduce false alerts, providing reliable monitoring for critical environments.

Why Thermal Buffers Matter for Accurate Monitoring

Temperature monitoring is often a NATA requirement for facilities maintaining accreditation. Guidelines recommend that sensors closely replicate the thermal properties of stored samples. Monitoring just the air temperature of a controlled environment is not enough—each sensor type responds to temperature changes differently based on thermal mass, material, and construction.

Air temperature changes rapidly during defrost cycles or door openings, often triggering false alarms, while the actual sample temperature remains largely unaffected. A proper thermal buffer provides confidence that your samples remain within acceptable limits and significantly reduces false alerts.

Shop now for Aluminium Temperature Buffers

Traditional thermal buffers are commonly made from ethylene glycol, chosen for its thermal inertia. They are often available in sizes like 10ml, 15ml, 30ml, or 65ml to match typical sample volumes. While glycol works well thermally, it poses risks if the container leaks or breaks—creating a mess, affecting readings, and potentially damaging samples.

Leak-Proof Aluminium Buffers for Precision Monitoring

Telemetry2U offers a superior alternative to liquid-based buffers: solid aluminium temperature buffers engineered to match sample volume and sensor specifications.

Available in 10ml, 15ml, 30ml, and 65ml equivalents, our aluminium buffers are precision-machined to never leak, degrade, or rust. Each unit has two precisely bored holes—one for your primary sensor and another for a reference sensor during calibration.

Having both sensors embedded in the same solid medium ensures extremely fast thermal stabilisation and enables quicker, more accurate calibrations. This setup is ideal for environments where reliability and calibration efficiency are critical.

Aluminium vs. Water Temperature Buffers: Comparative Performance

To evaluate the performance of aluminium temperature buffers compared to traditional water-based buffers, we conducted a controlled experiment. A temperature sensor was placed inside a 30ml water sample, and an identical sensor was embedded within our custom-designed aluminium buffer, both configured with a 1-minute logging interval.

After allowing both setups to stabilize at room temperature, they were suspended in air within an incubator set to 60°C, creating a temperature differential of approximately 40°C. Following 90 minutes, the incubator was turned off, and the door was left open to observe the cooling process.

The resulting temperature profiles from both sensors closely mirrored each other, demonstrating that our aluminium buffer effectively emulates the thermal response of a 30ml water sample. This confirms the aluminium buffer's suitability for accurate temperature monitoring in sensitive applications.

LoRaWAN-Based Temperature Monitoring Solutions

Telemetry2U uses the LoRaWAN (Long Range Wide Area Network) protocol to wirelessly transmit data to our secure cloud platform, allowing you to visualise temperature data in real time and receive alerts if values go out of range. LoRaWAN is a reliable network protocol, and there are many compatible temperature monitoring devices available.

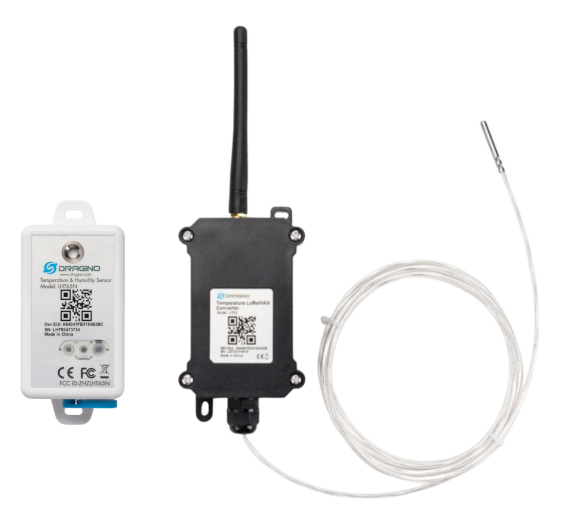

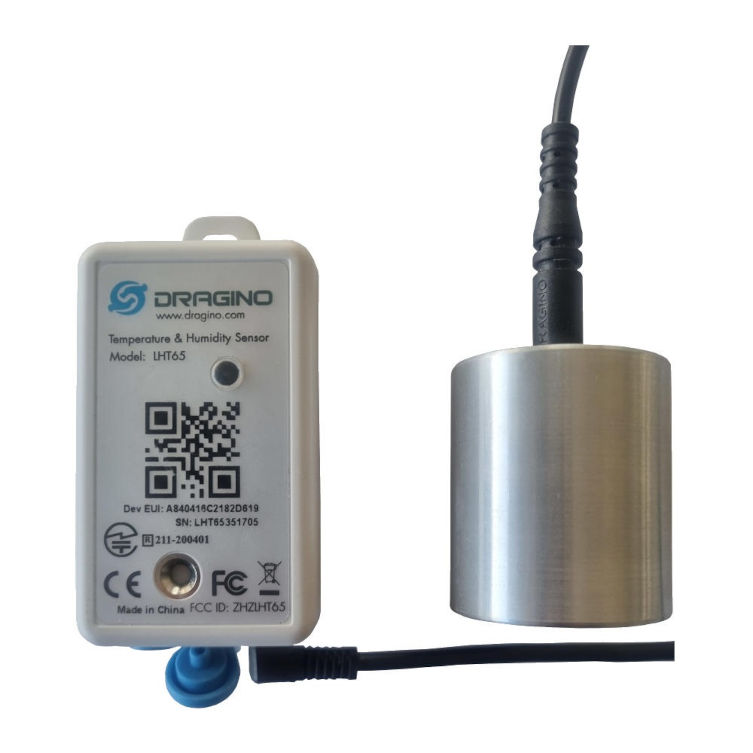

The Dragino LHT65 Temperature and Humidity Sensor includes both internal and external sensors, making it ideal for critical monitoring applications in hospitals, labs, and pharmacies.

The Dragino LTC2-LT Temperature Sensor uses a waterproof, high-precision PT-100 probe that measures temperatures from -196°C to 200°C—ideal for monitoring ultra-low temperature freezers, including -80°C storage.